Appendix 1 – Fire Resistance Test Procedures

for “A”, “B” and “F” Class Divisions

1 General

1.1 Approval of constructions will be restricted

to the orientation in which they have been tested; therefore, bulkheads,

linings and doors shall be tested vertically mounted and decks and

ceilings shall be tested horizontally mounted. It is only necessary

to test decks with the underside exposed to the heating conditions,

and "B" and "F" class ceilings and linings are required only to be

tested from the side incorporating the ceiling or the lining.

1.2 For "A" class bulkheads and doors for "general

application", i.e. for use of the insulation material on either side

of the structural core, and also for "B" class bulkheads and doors,

approval usually requires that the construction has been tested from

each side separately, using two separate specimens, unless the Administration

considers that only a single test to one side, that being the side

expected to provide a performance inferior to the other side, is appropriate.

1.3 In tests for "A" class bulkheads for "general

application" it may be possible for approval to be granted on the

basis of a single test only, provided that the bulkhead has been tested

in the most onerous manner, which is considered to be with the insulation

on the unexposed face and the stiffeners also on that side.

1.4 In tests for "A" class bulkheads for "restricted

application", i.e. where the fire hazard has been identified as being

from the insulated side only, the bulkhead can be tested with the

insulation on the exposed face and with the stiffeners also on that

side.

1.5 If approval of an "A" class bulkhead is being

sought involving the use of "double-sided application" of the insulation,

the thickness of the insulation being equal on both sides of the structural

core, it shall be tested with the stiffeners on the unexposed side

of the bulkhead, otherwise it shall be tested with the side with the

thinnest thickness of insulation on the exposed face.

1.6 The thickness of insulation on the stiffeners

need not be same as that of the steel plate.

1.7 If insulation of an "A" class division is

to be provided by membrane protection, i.e. by a "B" class ceiling

to a structural steel core or a "B" class lining to a structural steel

core, the distance between the membrane, i.e. the ceiling or the lining,

and the structural core shall be the minimum for which approval is

being sought. For "A" class bulkheads, the division is required to

be tested both from the structural core side, and from the "B" class

lining side. For both ceilings and linings which may form part of

such deck or bulkhead constructions, they shall satisfy at least "B-0"

classification.

1.8 When the insulation of an "A" class division

is provided by membrane protection, the stiffeners of the structural

core shall be positioned in the cavity between the steel plate of

the structural core and the membrane protection. For an "A" class

bulkhead the Administration may accept or require the stiffeners to

be on the opposite side of the steel plate of the structural core

to enable the distance between the membrane protection and the structural

core to be reduced to a minimum.

1.9 The dimensions of the structural cores of

the test specimens given in paragraph 2 are intended for structural

cores of stiffened flat plates of steel or aluminium alloy.

The Administration may require tests to be carried out on

specimens having structural cores of materials other than steel or

aluminium alloy if such materials are more representative of the construction

to be used on board ships.

1.10 "A" class divisions which consist of an uninsulated

steel bulkhead or deck of suitable scantlings and without openings

can be deemed to satisfy the requirements for class "A-0" divisions,

i.e. to satisfy the requirements for the passage of smoke and flame,

without the need for testing. All other divisions, including class

"A-0" divisions with a structural core of aluminium, are required

to be tested.

1.11 Results obtained on an insulating material

used in conjunction with an "A" class division may be applied to constructions

incorporating heavier scantlings than those tested and providing the

orientation of the construction is the same, i.e. results from bulkhead

tests shall not be applied to decks and vice versa.

1.12 The construction to be tested shall be, as

far as possible, representative of that to be used on board ships,

including the materials and method of assembly.

1.13 The designs of the specimens proposed in

this appendix are considered to reflect the worst case situations

in order to provide maximum usefulness of the classifications to end-use

applications. However, the Administration may accept or request special

test arrangements which provide additional information required for

approval, especially of those types of constructions which do not

utilize the conventional components of horizontal and vertical divisions,

e.g., where cabins may be of a modular type construction involving

continuous connections between bulkheads, decks and ceilings.

1.14 Doors, windows and other division penetrations

intended to be installed in fire divisions made of material other

than steel shall correspond to prototype(s) tested on a division made

of such material, unless the Administration is satisfied that the

construction, as approved, does not impair the fire resistance of

the division regardless of the division construction.

1.15 Constructions shall be tested without paint

or other superimposed finish, provided that where they are only produced

with a superimposed finish, and subject to the agreement of the Administration,

they may be tested as produced. Such constructions may be required

to be tested with a superimposed finish if such a finish is considered

by the Administration to have a detrimental effect on the performance

of the construction in the test.

1.16 "B" class constructions shall be tested without

finishes. For constructions where this is not possible, the finishes

may be included in the "B" class test specimen, and shall be included

in the non-combustibility test of the construction.

2 Nature of Test Specimens

2.1 “A” class bulkheads

2.1.1.1 The minimum overall dimensions of the

test specimen, including the perimeter details at the top, bottom

and vertical edges, are 2,440 mm width and 2,500 mm height. When the

maximum overall height in practice is less than that given above,

then the test specimen shall be of the maximum height to be used in

practice.

2.1.1.2 The minimum bulkhead panel height shall

be a standard height of the manufactured panel with a dimension of

2,400 mm.

2.1.1.3 The overall dimensions of the structural

core shall be 20 mm less in both the width and the height than the

overall dimensions of the specimen, and the other dimensions of the

structural core shall be as follows:

| – thickness of plating:

|

steel 4.5 ± 0.5 mm

|

|

|

aluminium 6.0 ± 0.5 mm

|

| – stiffeners spaced at 600

mm:

|

steel (65 ± 5) x (65 ± 5) x (6 ±

1) mm

|

|

|

aluminium (100 ± 5) x (75 ± 5)

x (9 ± 1) mm

|

2.1.1.4 The width of the structural core may be

greater than the specified dimensions providing that the additional

width is in increments of 600 mm to maintain the stiffener centres

and the relationship between the stiffeners and the perimeter detail.

2.1.1.5 Any joints in the plating shall be fully

welded, at least from one side.

2.1.1.6 The construction of a structural steel

core having the recommended dimensions is shown in figure 1; the thickness

of the plating and dimensions of the stiffeners shown are nominal

dimensions. Irrespective of the dimensions of the structural core

and the material of manufacture, the details around the perimeter

shall be as illustrated in figure 3.

2.1.2.1 Where insulation is provided by panels

(e.g., a "B" class lining), then the test specimen shall be such that

at least one of the panels is of full width and this, or these, shall

be positioned such that both its/their longitudinal edges are jointed

to an adjacent panel and are not secured to the restraint frame.

2.1.2.2 The overall dimensions of the panel insulation

system, including the perimeter details at all the edges, shall be

20 mm greater in each direction than the equivalent dimensions of

the structural core.

2.1.2.3 If the insulation system is a lining which

may incorporate electrical fittings, e.g., light fittings and/or ventilation

units, it is necessary that initially a test is performed on a specimen

of the lining itself, without the incorporation of these units, to

establish the basic performance. A separate test(s) shall be performed

on a specimen(s) with the units incorporated to ascertain their influence

on the performance of the lining.

2.1.2.4 Where the insulation consists of blankets,

the blankets shall be arranged so that not less than two transverse

joints between blankets are included. The joints shall be located

not less than 600 mm from the edges of the bulkhead.

2.1.3.1 The applicant shall provide full constructional

details of the test specimen in the form of drawings (including a

detailed schedule of components) and method of assembly, such that

the laboratory is able to confirm agreement between the actual specimen

and the drawings and specifications prior to the test. The drawings

shall include dimensions and details of the thicknesses of insulation

used in way of the plating and the stiffeners, the method of securing

the insulation system and details of the components used for this

purpose, details of joints, connections, air gaps and all other details.

2.1.3.2 Where insulation is provided by panels,

the manufacturer shall provide the information required in paragraphs

2.4.3 (bulkheads), 2.7.3 (linings) or 2.8.3 (ceilings). The distance

between the steel bulkhead/deck and the insulating membrane shall

be stated.

2.2 “A” class decks

2.2.1.1 The minimum overall dimensions of the

test specimen, including the perimeter details at all the edges, are

2,440 mm width and 3,040 mm length.

2.2.1.2 The overall dimensions of the structural

core shall be 20 mm less in both the width and length than the overall

dimensions of the specimen, and the other dimensions of the structural

core shall be as follows:

| – thickness of

plating:

|

steel 4.5 ± 0.5 mm

|

|

|

aluminium 6 ± 0.5

mm

|

| – stiffeners spaced at 600

mm:

|

steel (100 ± 5) x (70 ± 5) x (8

± 1) mm

|

|

|

aluminium (150 ± 5) x (100 ± 5)

x (9 ± 1) mm

|

2.2.1.3 The width of the structural core may be

greater than the specified dimensions providing that the additional

width is in increments of 600 mm to maintain the stiffener centres

and the relationship between the stiffeners and the perimeter detail.

2.2.1.4 Any joints in the plating shall be fully

welded, at least from one side.

2.2.1.5 The construction of a structural steel

core having the recommended dimensions is shown in figure 2; the thickness

of the plating and dimensions of the stiffeners shown are nominal

dimensions. Irrespective of the dimensions of the structural core

and the material of manufacture, the details around the perimeter

shall be as illustrated in figure 3.

2.2.2.1 Where insulation is provided by panels

(e.g., a "B" class ceiling), then the test specimen shall be designed

such that at least one of the panels is of full width and this, or

these, shall be positioned such that both its/their longitudinal edges

are jointed to an adjacent panel and are not secured to the restraint

frame. The overall dimensions of the panel insulation system, including

the perimeter details at all the edges, shall be 20 mm greater in

each direction than the equivalent dimensions of the structural core.

2.2.2.2 If the ceiling incorporates panels, the

specimen shall include examples of both the lateral and longitudinal

joints between the panels. If the specimen is to simulate a ceiling

where the maximum length of the panels is greater than the length

of the specimen, then a joint shall be positioned at a distance of

approximately 600 mm from one of the shorter ends of the test specimen.

2.2.2.3 If the insulation system is a ceiling

which may incorporate electrical fittings, e.g., light fittings and/or

ventilation units, it is necessary that initially a test is performed

on a specimen of the ceiling itself, without the incorporation of

these units, to establish the basic performance. A separate test(s)

shall be performed on a specimen(s) with the units incorporated to

ascertain their influence on the performance of the ceiling.

2.2.2.4 Where the insulation consists of blankets,

the blankets shall be arranged so that not less than two transverse

joints between blankets are included. The joints shall be located

not less than 600 mm from the edges of the deck.

2.2.3.1 The applicant shall provide full constructional

details of the test specimen in the form of drawings (including a

detailed schedule of components) and method of assembly, such that

the laboratory is able to confirm agreement between the actual specimen

and the drawings and specifications prior to the test. The drawings

shall include dimensions and details of the thicknesses of insulation

used in way of the plating and the stiffeners, the method of securing

the insulation system and details of the components used for this

purpose, details of joints, connections, air gaps and all other details.

2.2.3.2 Where insulation is provided by panels,

the manufacturer shall provide the information required in paragraph

2.8.3 (ceilings). The distance between the steel deck and the insulating

membrane shall be stated.

2.3 “A” class doors

The test specimen shall incorporate the maximum size (in

terms of both the width and the height) of door leaf or leaves for

which approval is to be sought. The maximum size of a door which can

be tested will be determined by the requirement to retain certain

dimensions of the structural core (see paragraph 2.3.2.4 below).

2.3.2.1 The door leaf and frame shall be constructed

of steel or other equivalent material and insulated as necessary to

achieve the desired standard of insulation.

2.3.2.2 Door furniture such as hinges, locks,

latches, shoot bolts, handles, etc., shall be constructed of materials

having melting points of not less than 950°C unless it can be

shown by the fire test that materials having melting points below

950°C do not adversely affect the performance of the door.

2.3.2.3 The door leaf and frame shall be mounted

into a structural core constructed in accordance with paragraph 2.1.1.

2.3.2.4 An opening to accommodate the door assembly

shall be provided in the structural core; the maximum dimensions of

the opening will be determined by a requirement to retain a minimum

width of the structural core of 300 mm to each vertical side of the

opening and a minimum distance of 100 mm from the top edge of the

structural core.

2.3.2.5 No additional stiffening shall be provided

to the structural core unless provided as part of the door frame.

2.3.2.6 The method of fixing the door frame into

the opening in the structural core shall be as used in practice. If

the method of fixing the door frame in a test is made by bolts, the

Administration may also accept welding as a method of fixing the door

frame without further tests.

2.3.2.7 For doors mounted in a three-sided frame,

the door shall be mounted with a bottom gap of between 12 mm and 25

mm between the bottom of the door and the test frame.

2.3.2.8 The structural core shall be mounted such

that the stiffeners are on the unexposed face and the insulating system

shall be on the exposed face.

2.3.2.9 The insulation system shall be approved

by the Administration to at least the same standard as that which

the door is intended to achieve. If the insulation performance of

the door is unknown the structural core shall be insulated to "A-60"

standard. The insulation of the structural core shall not be extended

beyond the outer web of the door frame.

2.3.2.10 The door shall be mounted into the structural

core such that the side expected to give the inferior performance

will be exposed to the heating conditions of the test.

2.3.2.11 A hinged door shall be tested with the

door leaf opening away from the heating conditions unless the Administration

deems otherwise.

2.3.2.12 For sliding doors it is not possible

to state generally from which side the door shall be tested to give

the inferior performance. It will, therefore, be necessary to conduct

two separate tests, one with the door mounted to the exposed face

and one with the door mounted to the unexposed face of the bulkhead.

If, for practical reasons, a sliding door cannot be fixed to the stiffened

face of the structural core, then, subject to the agreement of the

Administration, the stiffeners may be positioned on the exposed face.

2.3.2.13 Lift landing doors can be expected to

be exposed to fire from the corridor side only, and they shall be

exposed to fire test heating conditions from that side only.

2.3.2.14 Tests performed with double leaf doors

will not be accepted as approval documentation for single leaf doors.

2.3.2.15 Double leaf doors should be tested with

equally sized door leaves unless the door is intended to have unequally

sized leaves.

The applicant shall provide full constructional details

of the test specimen in the form of drawings (including a detailed

schedule of components) and method of assembly, such that the laboratory

is able to confirm agreement between the actual specimen and the drawings

and specifications prior to the test. The drawings shall include dimensions

and details of the following:

-

.1 the bulkhead;

-

.2 the door leaf and frame construction, including

the clearances between the door leaf and the frame;

-

.3 the connection of the door frame to the bulkhead;

-

.4 the method of securing insulation and details

of components used for this purpose (e.g., the type and rate of application

of any adhesive); and

-

.5 fittings such as hinges, shoot bolts, latches,

locks, etc.

2.4 "B" and "F" class bulkheads

2.4.1.1 The minimum overall dimensions of the

test specimen, including the perimeter details at the top, bottom

and vertical edges, are 2,440 mm width and 2,500 mm height. When the

maximum overall height in practice is to be less than that given above,

then the test specimen shall be of the maximum height to be used in

practice.

2.4.1.2 The minimum bulkhead panel height shall

be a standard height of the manufactured panel with a dimension of

2,400 mm.

2.4.2.1 Where the construction incorporates panels,

the specimen shall be constructed such that at least one of the panels

is of full width and this, or these, shall be positioned such that

both its/their longitudinal edges are jointed to an adjacent panel

and are not secured to the restraint frame.

2.4.2.2 If the bulkhead may incorporate electrical

fittings, e.g., light fittings and/or ventilation units, it is necessary

that initially a test is performed on a specimen of the bulkhead itself,

without the incorporation of these units, to establish the basic performance.

A separate test(s) shall be performed on a specimen(s) with the units

incorporated to ascertain their influence on the performance of the

bulkhead.

The applicant shall provide full constructional details

of the test specimen in the form of drawings (including a detailed

schedule of components) and method of assembly, such that the laboratory

is able to confirm agreement between the actual specimen and the drawings

and specifications prior to the test. The drawings shall include dimensions

and details of the thicknesses of materials used in the insulation

system (e.g., of any panels), the method of securing the panels and

details of the components used for this purpose, details of joints,

connections, air gaps and all other details.

2.5 "B" and "F" class decks

2.5.1.1 The minimum overall dimensions of the

test specimen, including the perimeter details at all the edges, are

2,440 mm width and 3,040 mm length.

2.5.1.2 When the maximum dimensions in practice

are less than that given above, the test specimen shall be of the

maximum size to be used in practice and the tested width shall be

reported.

Where the construction incorporates panels, the specimen

shall be constructed such that at least one of the panels is of full

width and this, or these, shall be positioned such that both its/their

longitudinal edges are jointed to an adjacent panel and are not secured

to the restraint frame.

The applicant shall provide full constructional details

of the test specimen in the form of drawings (including a detailed

schedule of components) and method of assembly, such that the laboratory

is able to confirm agreement between the actual specimen and the drawings

and specifications prior to the test. The drawings shall include dimensions

and details of the thicknesses of materials used in the insulation

system (e.g., of any panels), the method of securing the insulation

system and details of the components used for this purpose, details

of joints, connections, air gaps and all other details.

2.6 "B" and "F" class doors

The test specimen shall incorporate the maximum size (in

terms of both the width and the height) of the door leaf or leaves

for which approval is to be sought. The maximum size of a door which

can be tested will be determined by the requirement to retain certain

dimensions of the bulkhead (see paragraph 2.6.2.6).

2.6.2.1 Door furniture such as hinges, locks,

latches, shoot bolts, handles, etc., shall be constructed of materials

having melting points of not less than 850°C unless it can be

shown by the fire test that materials having melting points below

850°C do not adversely affect the performance of the door.

2.6.2.2 The door leaf and frame shall be mounted

as appropriate into a "B" or "F" class bulkhead of compatible construction,

thereby reflecting an actual end-use situation. The bulkhead shall

have dimensions as prescribed in paragraph 2.4.1.

2.6.2.3 The bulkhead shall be of a construction

approved by the Administration as having at least a similar classification

to that required by the door, and approval shall be limited to the

type of construction in which the door was tested.

2.6.2.4 The method of fixing the door frame to

the bulkhead shall be as used in practice. If the method of fixing

the door frame in a test is made by bolts, the Administration may

also accept welding as a method of fixing the door frame without further

tests.

2.6.2.5 For doors mounted in a three-sided frame,

the door shall be mounted with a bottom gap of between 12 mm and 25

mm between the bottom of the door and the test frame.

2.6.2.6 The door shall be positioned such that

there is a minimum width of the bulkhead of 300 mm to each vertical

side of the door and a minimum distance of 100 mm from the top edge

of the bulkhead.

2.6.2.7 The door shall be mounted into the bulkhead

such that the side expected to give the inferior performance will

be exposed to the heating conditions of the test.

2.6.2.8 A hinged door shall be tested with the

door leaf opening away from the heating conditions unless the Administration

deems otherwise.

2.6.2.9 For sliding doors it is not possible to

state generally from which side the door shall be tested to give the

inferior performance. It will, therefore, be necessary to conduct

two separate tests, one with the door mounted to the exposed face

and one with the door mounted to the unexposed face of the bulkhead.

2.6.2.10 For a door which incorporates a ventilation

opening within its construction, the ventilation grille(s) shall be

open at the commencement of the test.

The applicant shall provide full constructional details

of the test specimen in the form of drawings (including a detailed

schedule of components) and method of assembly, such that the laboratory

is able to confirm agreement between the actual specimen and the drawings

and specifications prior to the test. The drawings shall include dimensions

and details as follows:

-

.1 the bulkhead;

-

.2 the door leaf and frame construction, including

the clearances between the door leaf and the frame;

-

.3 the connection of the door frame to the bulkhead;

-

.4 the method of securing insulation and details

of components used for this purpose (e.g., the type and rate of application

of any adhesive); and

-

.5 fittings such as hinges, shoot bolts, latches,

locks, handles, ventilation louvres, escape panels, etc.

2.7 "B" and "F" class linings

Linings shall be tested as bulkheads and they shall be exposed

to the fire test heating conditions from the side intended to face

the cabin.

2.7.1.1 The minimum overall dimensions of the

test specimen, including the perimeter details at the top, bottom

and vertical edges, are 2,440 mm width and 2,500 mm height. When the

maximum overall height in practice is to be less than that given above,

then the test specimen shall be of the maximum height to be used in

practice.

2.7.1.2 The minimum bulkhead panel height shall

be a standard height of the manufactured panel with a dimension of

2,400 mm.

2.7.2.1 The lining shall be positioned alongside

a structural core constructed in accordance with paragraph 2.1.1.

The design of the lining shall be such that it facilitates its assembly

with the limited access provided by the proximity of the structural

core, i.e. it shall be mounted with the structural core in place.

-

Note: Viewing and access openings on an "A" class

bulkhead may be provided for the determination of the integrity of

the lining, and they should be located corresponding to joints of

panels of the lining and away from thermocouples on an "A" class bulkhead.

They should normally be sealed with mineral wool insulation slabs

except when viewing or access to the lining is needed.

2.7.2.2 During a test on an "A" class bulkhead

which utilizes membrane protection along its exposed side, e.g., a

"B" class lining, it is possible also to evaluate the performance

of the lining with a view to classification providing that the necessary

thermocouples are attached to the lining and providing that the necessary

integrity measurements are made.

2.7.2.3 The specimen shall be constructed such

that at least one of the panels is of full width and this, or these,

shall be positioned such that both its/their longitudinal edges are

jointed to an adjacent panel and are not secured to the restraint

frame.

2.7.2.4 If the lining may incorporate electrical

fittings, e.g., light fittings and/or ventilation units, it is necessary

that initially a test is performed on a specimen of the lining itself,

without the incorporation of these units, to establish the basic performance.

A separate test(s) shall be performed on a specimen(s) with the units

incorporated to ascertain their influence on the performance of the

lining.

The applicant shall provide full constructional details

of the test specimen in the form of drawings (including a detailed

schedule of components) and method of assembly, such that the laboratory

is able to confirm agreement between the actual specimen and the drawings

and specifications prior to the test. The drawings shall include dimensions

and details of the thicknesses of materials used in the insulation

system (e.g., of any panels), the method of securing the insulation

system and details of the components used for this purpose, details

of joints, connections, air gaps and all other details.

2.8 "B" and "F" class ceilings

2.8.1.1 The minimum overall dimensions of the

test specimen, including the perimeter details at all the edges, are

2,440 mm width and 3,040 mm length.

2.8.1.2 When the maximum dimensions in practice

are less than those given above then the test specimen shall be of

the maximum size to be used in practice, and the tested width shall

be reported.

2.8.2.1 The ceiling shall be positioned below

a structural core constructed in accordance with paragraph 2.2.1.

The design of the ceiling shall be such that it facilitates its assembly

with the limited access provided by the proximity of the structural

core, i.e. it shall be mounted with the structural core in place.

-

Note: Viewing and access openings on an "A" class

deck may be provided for the determination of the integrity of the

ceiling, and they should be located corresponding to joints of panels

of the ceiling and away from thermocouples on an "A" class deck. They

should normally be sealed with mineral wool insulation slabs except

when viewing or access to the ceiling is needed.

2.8.2.2 During a test on an "A" class deck which

utilizes membrane protection along its underside, e.g., a "B" class

ceiling, it is possible also to evaluate the performance of the ceiling

with a view to classification providing that the necessary thermocouples

are attached to the ceiling and providing that the necessary integrity

measurements are made.

2.8.2.3 If the ceiling incorporates panels, the

specimen shall include examples of both the lateral and longitudinal

joints between the panels. If the specimen is to simulate a ceiling

where the maximum length of the panels is greater than the length

of the specimen, then a joint shall be positioned at a distance of

approximately 600 mm from one of the shorter ends of the test specimen.

2.8.2.4 The specimen shall be constructed such

that at least one of the panels is of full width and this, or these,

shall be positioned such that both its/their longitudinal edges are

jointed to an adjacent panel and are not secured to the restraint

frame.

2.8.2.5 If the ceiling may incorporate electrical

fittings, e.g., light fittings and/or ventilation units, it is necessary

that initially a test is performed on a specimen of the ceiling itself,

without the incorporation of these units, to establish the basic performance.

A separate test(s) shall be performed on a specimen(s) with the units

incorporated to ascertain their influence on the performance of the

ceiling.

2.8.2.6 Where testing is conducted on a perforated

ceiling system, equally constructed non-perforated ceilings and ceilings

with a lesser degree of perforations (in terms of size, shape, and

perforations per unit area) may be approved without further testing.

The applicant shall provide full constructional details

of the test specimen in the form of drawings (including a detailed

schedule of components) and method of assembly, such that the laboratory

is able to confirm agreement between the actual specimen and the drawings

and specifications prior to the test. The drawings shall include dimensions

and details of the thicknesses of materials used in the insulation

system (e.g., of any panels), the method of securing the insulation

system and all relevant details including, in particular, the components

used for this purpose, joints, connections and air gaps.

3 Materials for Test Specimens

3.1 Specifications

Prior to the test, the following information, if applicable,

shall be submitted to the laboratory by the applicant for each of

the materials used in the construction:

-

.1 the identification mark and trade name;

-

.2 principal details of composition

-

.3 nominal thickness;

-

.4 nominal density (for compressible materials

this shall be related to the nominal thickness);

-

.5 nominal equilibrium moisture content (at relative

humidity of 50% and a temperature of 23°C);

-

.6 nominal organic content;

-

.7 specific heat at ambient temperature; and

-

.8 thermal conductivity at ambient temperature.

3.2 Control measurements

3.2.1.1 The testing laboratory shall take reference

specimens of all those materials whose characteristics are important

to the performance of the specimen (excluding steel and equivalent

material). The reference specimens shall be used for the non-combustibility

test, if appropriate, and for the determination of the thickness,

the density and, where appropriate, the moisture and/or organic content.

3.2.1.2 The reference specimens for sprayed materials

shall be made when the material is sprayed on the structural core

and they shall be sprayed in a similar manner and in the same orientation.

3.2.1.3 The laboratory shall conduct the following

control tests, as appropriate to the type of material and the proposed

classification, on the reference specimens after they have been conditioned

as specified in paragraph 4.

3.2.1.4 For the determination of the thickness,

the density and the moisture and/or organic content three specimens

shall be used, and the value quoted as the mean of the three measurements.

3.2.2

Encapsulated materials

3.2.2.1 When an insulation material is encapsulated

within the construction and it is not possible for the laboratory

to take specimens of the material prior to the test for conducting

the control measurements, the applicant shall be requested to provide

the requisite samples of the material. In these cases it shall be

clearly stated in the test report that the measured properties were

determined from samples of the material provided by the applicant

for the test.

3.2.2.2 Notwithstanding the above, the laboratory

shall attempt, wherever possible, to verify the properties by using

samples which may be cut from the specimen before test or by checking

against similar properties determined after test. When samples of

the material are cut from the test specimen before test, the specimen

shall be repaired in a manner such that its performance in the fire

test is not impaired.

Where materials used in the construction of the specimen

are required to be non-combustible, i.e. for "A" and "B" classes,

evidence in the form of test reports in accordance with the test method

in part 1 of this annex, and from

a testing laboratory recognized by the Administration and independent

of the manufacturer of the material shall be provided. These test

reports shall indicate that the non-combustibility tests were conducted

not more than 24 months prior to the date of the performance of the

fire resistance test. If such reports cannot be provided then tests

in accordance with part 1 of annex

1 to the Code shall be conducted. When the material has a type approval

certificate for non-combustible material valid at the performance

of the fire resistance test, non-combustibility test reports may not

be required.

3.2.4

Low flame-spread characteristics

3.2.4.1 Where materials used in the construction

of the specimen are required to have low flame-spread characteristics,

evidence in the form of test reports in accordance with part 5 of this annex, and from a testing

laboratory recognized by the Administration and independent of the

manufacturer of the material shall be provided. These test reports

shall indicate that the low flame-spread tests were conducted not

more than 24 months prior to the date of the performance of the fire

resistance test. If such reports cannot be provided then tests in

accordance with part 5 of this

annex shall be conducted. When the material has a type approval certificate

for low flame-spread characteristics valid at the performance of the

fire resistance test, low flame-spread test reports may not be required.

3.2.4.2 Adhesives used in the construction of

the specimen are not required to be non-combustible; however, they

shall have low flame-spread characteristics.

3.2.5.1 The thickness of each material and combination

of materials shall be ± 10% of the value stated as the nominal

thickness when measured by using a suitable gauge or callipers.

3.2.5.2 The thickness of a sprayed insulation

material shall be measured using a suitable probe at positions adjacent

to each of the unexposed-face thermocouples.

3.2.6.1 The density of each material shall be

determined from measurement of the weight and the dimensions.

3.2.6.2 The density of mineral wool or any similar

compressible material shall be related to the nominal thickness and

the density of each material used in the test specimen shall be ±

10% of the value stated as the nominal density.

3.2.7.1 The moisture content (W1-W2)

of each non-combustible material used in the specimen shall be calculated

using the following method, and indicate a percentage of the dry weight

(W2), and which information is required.

3.2.7.2 In the following, W1, W2 and

W3 are mean values of three weight measurements. W1 shall

be higher than 25 g. Three specimens of each material, taken in the

width of the production's direction and measuring width x minimum

20 mm x thickness of the material, shall be weighed (initial conditioned

weight W1) and then heated in a ventilated oven at a temperature

of 105 ± 2°C for 24 h and reweighed when cooled (W2).

However, gypsum-based, cementations and similar materials should be

dried at a temperature of 55 ± 5°C to constant weight (W2).

3.2.7.3 The moisture content (W1-W2)

of each specimen shall be calculated as a percentage of the dry weight

(W2).

3.2.8.1 The information of organic content of

non-combustible materials used in the specimen is required. After

the percentage moisture contents have been calculated as specified

in paragraph 3.2.7, the three specimens should be further heated in

an oven at a temperature of 500 ± 20°C for 2 h and again

weighed (W3). The organic content (W2-W3)

shall be calculated as a percentage of the dry weight (W2).

3.2.8.2 The organic content of each material used

in the test specimen should be within ± 0.3% absolute of the

value stated as the nominal organic content.

4 Conditioning of the Test Specimens

4.1 General

4.1.1 The test specimen should be protected against

adverse environmental conditions until the time of the test. The test

specimen shall not be tested until it has reached an equilibrium (constant

weight), air-dry condition under the laboratory's normal ambient condition.

The equilibrium condition shall be obtained according to paragraph

4.2 below.

4.1.2 Accelerated conditioning is permissible

provided the method does not alter the properties of component materials.

In general, high-temperature conditioning shall be below temperatures

critical for the materials.

4.2 Verification

4.2.1 The condition of the test specimen can be

monitored and verified by use of special samples for the determination

of moisture content of constituent materials, as appropriate. These

samples shall be so constructed as to represent the loss of water

vapour from the specimen by having similar thicknesses and exposed

faces. They shall have minimum linear dimensions of 300 mm by 300

mm and a minimum mass of 100 g. Constant weight shall be considered

to be reached when two successive weighing operations, carried out

at an interval of 24 h, do not differ by more than 0.3% of the mass

of the reference specimen or 0.3 g, whichever is the greater.

4.2.2 Other reliable methods of verifying that

the material has reached equilibrium moisture content may be used

by the testing laboratory.

4.3 Encapsulated materials

4.3.1 When the test specimen incorporates encapsulated

materials it is important to ensure that these materials have reached

an equilibrium moisture content prior to assembly, and special arrangements

shall be made with the applicant for the test to ensure that this

is so.

4.3.2 When the test specimen, such as doors, incorporates

encapsulated materials, the requirement relevant to equilibrium moisture

in paragraph 4.2 shall apply.

5 Mounting of the Test Specimens

5.1 Restraint and support frames

5.1.1 All test specimens shall be mounted within

substantial concrete, or concrete- or masonry-lined frames, which

are capable of providing a high degree of restraint to the expansion

forces generated during the tests. The concrete or the masonry shall

have a density between 1,600 kg/m3 and 2,400 kg/m3.

The concrete or masonry lining to a steel frame shall have a thickness

of at least 50 mm.

5.1.2 The rigidity of the restraint frames shall

be evaluated by applying an expansion force of 100 kN within the frame

at mid-width between two opposite members of the frame and measuring

the increase in the internal dimensions at these positions. This evaluation

shall be conducted in the direction of the bulkhead or deck stiffeners,

and the increase of the internal dimension shall not exceed 2 mm.

5.1.3 For frames which are to be used to evaluate

"A" class divisions which incorporate "B" class ceilings or linings,

the frames shall be provided with at least four viewing and access

openings, notionally one to each quarter of the test specimen. These

openings shall facilitate access to the cavity for the determination

of the integrity of the ceiling or lining during the test on the deck

or bulkhead. The access/viewing openings shall normally be sealed

with mineral wool insulation slabs except when viewing or accessing

to the ceiling or lining is needed.

5.2 "A" class divisions

5.2.1 The structural core to an "A" class division

shall be fixed into the restraint frame and sealed around its perimeter

as shown in figure 3. Steel spacers, with an approximate thickness

of 5 mm, may be inserted between the fixing cleats and the restraint

frame if the laboratory finds this necessary.

5.2.2 When the structural core of an "A" class

division is to be exposed to the heating conditions of the test, i.e.

when the fixing cleats are on the exposed side of the structural core,

then a 100 mm wide perimeter margin adjacent to the restraint frame

shall be insulated such that the fixing cleats and the edges of the

structural core are protected from direct exposure to the heating

conditions. In no other situations, irrespective of the type of test

specimen, shall the perimeter edges be protected from direct exposure

to the heating conditions.

5.3 "B" and "F" class divisions

5.3.1 For a "B" or "F" class bulkhead or lining,

the specimen shall be supported at the top and secured on the vertical

sides and at the bottom in a manner representative of the conditions

in service. The support provided at the top of a bulkhead or lining

shall allow for the appropriate expansion or clearance to be used

as in practice. At the vertical edges lateral expansion towards the

vertical edges of the restraint frame shall be prevented by ensuring

a tight fit of the specimen within the frame which may be achieved

by inserting a rigid packing between the vertical edges and the frame.

If provision for movement at the edges of a bulkhead or lining is

made for a particular construction in service, the specimen shall

simulate these conditions.

5.3.2 For a "B" or "F" class ceiling, expansion

of the ceiling members shall be prevented at the perimeter edges since

the specimen is intended to simulate a part of a ceiling removed from

a much greater area. Expansion shall be prevented by ensuring a tight

fit of the specimen within the frame which may be achieved by inserting

a rigid packing between the ends or edges of ceiling members and the

restraint frame. Only if the ceiling is being tested at full size

in one or more directions is it allowed to incorporate the expansion

allowance at the perimeter edges in the appropriate direction or directions.

6 Examination of the Test Specimens

6.1 Conformity

6.1.1 The laboratory shall verify the conformity

of the test specimen with the drawings and method of assembly provided

by the applicant (see paragraph 2), and any area of discrepancy shall

be resolved prior to commencement of the test.

6.1.2 On occasion it may not be possible to verify

the conformity of all aspects of the specimen construction prior to

the test and adequate evidence may not be available after test. When

it is necessary to rely on information provided by the applicant then

this shall be clearly stated in the test report. The laboratory shall

nevertheless ensure that it fully appreciates the design of the test

specimen and shall be confident that it is able to accurately record

the constructional details in the test report.

6.2 Door clearances

Following mounting of the door and immediately prior to

test, the laboratory shall measure the actual clearances between the

door leaf and the door frame, and additionally for a double leaf door

between the adjacent door leaves. The clearances shall be measured

for each door leaf at two positions along the top and bottom edges

and at three positions along each vertical edge.

6.3 Door operation

Similarly, immediately prior to test, the laboratory shall

check the operability of the door by opening the door leaf by a distance

of at least 300 mm. The door leaf shall then be closed, either automatically,

if such a closing device is provided, or manually. The door may be

latched for the test but shall not be locked, and no devices for latching

or locking shall be included which are not normally incorporated in

practice.

7 Instrumentation

7.1 General

The instrumentation of the furnace and the instrumentation

of the test specimen shall generally be in accordance with the standard

ISO 834-1, Fire resistance tests – Elements of building construction

– Part 1: General requirements; except where amended by this

section. The details given in the following paragraphs are supplementary

to, an elaboration of, or a deviation from the ISO requirements.

7.2 Ambient temperature thermocouple

A thermocouple shall be used to indicate the ambient temperature

within the laboratory in the vicinity of the test specimen both prior

to and during the test period. The thermocouple shall be nominally

of 3 mm diameter, mineral insulated, stainless steel type K. The measuring

junction shall be protected from radiated heat and draught. The ambient

temperature shall be monitored at a distance of between 1 m and 3

m horizontally away from the unexposed face of the test specimen.

7.3 Furnace temperature thermocouples

7.3.1.1 The furnace thermocouples shall be plate

thermometers, which comprise an assembly of a folded steel plate,

a thermocouple fixed to it and containing insulation material as described

in standard ISO 834-1.

7.3.1.2 The plate part shall be constructed from

150 ± 1 mm long by 100 ± 1 mm wide by 0.7 ± 0.1

mm thick nickel alloy sheet strips folded to the design as shown in

figure 4

7.3.1.3 The measuring junction shall consist of

nickel chromium/nickel aluminium (type K) wire as defined in standard

IEC 60584-1, contained within mineral insulation in a heat-resisting

steel alloy sheath of nominal diameter 1 mm, the hot junctions being

electrically insulated from the sheath. The thermocouple hot junction

shall be fixed to the geometric centre of the plate in the position

shown in figure 4 by a small steel strip made from the same material

as the plate. The steel strip can be welded to the plate or may be

screwed to it to facilitate replacement of the thermocouple. The strip

shall be approximately 18 mm by 6 mm if it is spot welded to the plate,

and nominally 25 mm by 6 mm if it is to be screwed to the plate. The

screws shall be 2 mm in diameter.

7.3.1.4 The assembly of plate and thermocouple

shall be fitted with a pad of inorganic insulation material nominally

97 ± 1 mm by 97 ± 1 mm by 10 ± 1 mm thick, density

280 ± 30 kg/m3.

7.3.1.5 Before the plate thermometers are first

used, the complete plate thermometer shall be aged by immersing in

a pre-heated oven at 1,000°C for 1 h.

7.3.1.6 When a plate thermometer is used more

than once, a log of its use shall be maintained indicating, for each

use, the checks made and duration of use. The thermocouple and the

insulation pad shall be replaced after 50 h exposure in the furnace.

At least six furnace thermocouples shall be provided for

the specimens given in paragraph 2. For specimens larger than those

specified in paragraph 2, additional thermocouples shall be provided

in the proportion of one per 1.5 m2 of the specimen area.

In case of a door assembly, specimen area refers to the entire bulkhead

construction with the door fitted. This principle shall be used also

for the other assemblies (e.g., windows, ducts and penetrations) installed

in bulkheads or decks.

7.3.3.1 The thermocouples employed to measure

the temperature of the furnace shall be uniformly distributed so as

to give a reliable indication of the average temperature in the vicinity

of the specimen. At the commencement of the test the measuring junctions

shall be 100 mm from the face of the specimen and they shall be maintained

at a distance of 50 mm to 150 mm during the test. The method of support

shall ensure that thermocouples do not fall away or become dislodged

during the test. Where it is convenient to pass thermocouple wires

through the test construction, then the steel support tube shall not

be used. The plate thermometers shall not be located at positions

within the furnace where they are subject to direct flame impingement.

7.3.3.2 The plate thermometer shall be orientated

so that side A faces the back wall of the wall furnace and the floor

of the horizontal furnace.

The thermocouple wire shall be either continuous to the

recording instrument or suitable compensating wire shall be used with

all junctions maintained as near as possible at ambient temperature

conditions

7.4 Furnace pressure sensors

The mean value of the furnace pressure shall be measured

using one of the designs of sensing heads described in figure 5.

7.5 Unexposed-face temperature thermocouples

The temperature of the unexposed surface shall be measured

by means of disc thermocouples of the type shown in figure 6. Thermocouple

wires, 0.5 mm in diameter, shall be soldered to a 0.2 mm thick by

12 mm diameter copper disc. Each thermocouple shall be covered with

a 30 mm square x 2.0 ± 0.5 mm thick non-combustible insulating

pad. The pad material shall have a density of 900 ± 100 kg/m3.

Connection to the recording instrument shall be by wires

of similar or appropriate compensating type.

7.5.3

Preparation of surfaces to receive

thermocouples

7.5.3.1 Steel – Surface finishes shall be

removed and the surface cleaned with a solvent. Loose rust and scale

shall be removed by wire brush.

7.5.3.2 Irregular surfaces – A smooth surface,

not greater than 2,500 mm2, to provide adequate adhesive

bond shall be made for each thermocouple by smoothing the existing

surface with a suitable abrasive paper. The material removed shall

be the minimum to provide an adequate bonding surface. Where the surface

cannot be smoothed, fillings shall be used of minimum quantity to

provide a suitable surface. The filling shall comprise a ceramic cement

and when the filled surface is dry it shall be smoothed, if necessary,

with abrasive paper.

7.5.4

Fixing of thermocouples

7.5.4.1 Steel – The insulating pad with

the thermocouple fitted shall be bonded to the cleaned surface of

the steel using a "water-based ceramic cement" produced by integrating

the components to form a high-temperature-resistant adhesive. The

adhesive shall be of such a consistency that no mechanical aid is

necessary for retention purposes during the drying process, but, where

difficulty in bonding is experienced, retention by adhesive tape may

be employed provided that the tape is removed sufficiently long in

advance of the test to allow complete drying of the adhesive. Care

is required in the removal of the tape to ensure that the insulating

pad is not damaged. If the thermocouple pad is damaged when the tape

is removed then the thermocouple shall be replaced.

7.5.4.2 Mineral wool – The thermocouples

with insulating pads fitted shall be arranged in such a way that if

a surface wire mesh is present it may aid retention, and in all cases

the bond to the fibrous surface shall be made using a "contact adhesive".

The nature of the adhesive necessitates a drying time before mating

surfaces are put together, thus obviating the need for external pressure.

7.5.4.3 Where gluing is not possible, pins, screws

or clips which are only in contact with those parts of the pad which

are not over the (copper) disc shall be used. (Example: U-shaped clips

approximately 30 x 15 x 30 x 0.5 mm, which are in contact only with

the extreme corners of the pad. Heat transfer to the copper disc is

negligible.)

7.5.4.4 Mineral fibre spray – Thermocouples

shall not be fitted until the insulation has reached a stable moisture

condition. In all cases the bonding technique for steel shall be used

and where a surface wire mesh is present the thermocouples shall be

affixed to the insulation in such a way that the wire mesh aids retention.

7.5.4.5 Vermiculite/cement type spray –

The technique specified for wet fibrous spray shall be employed.

7.5.4.6 Boards of fibrous or mineral aggregate

composition – The bonding technique for steel shall be used.

7.5.4.7 In all cases of adhesive bonding, the

adhesive shall be applied in a thin film sufficient to give an adequate

bond and there shall be a sufficient lapse of time between the bonding

of the thermocouples and the test for stable moisture conditions to

be attained in the case of the ceramic adhesive and evaporation of

the solvent in the case of the "contact adhesive".

7.5.4.8 For "A" and "B" class divisions the insulation

performance of a construction shall be given by that part of the construction

which is manufactured from non-combustible materials only. However,

if a material or panel is only produced with a superimposed finish,

or if the Administration considers that the addition of a superimposed

finish may be detrimental to the performance of the division, the

Administration may allow, or may require, the finish to be incorporated

during the test. In these cases, the superimposed finish shall be

removed locally over an area as small as possible to allow fixing

of the thermocouples to the non-combustible part, e.g., a deck provided

with overlaid non-combustible insulation (a floating floor) shall

have any combustible top surface finish removed locally to the thermocouples

to allow them to be fixed to the insulation material.

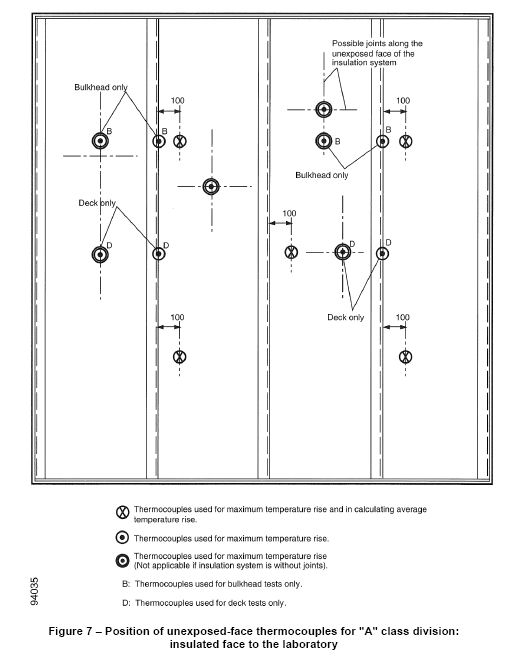

7.6 Positioning of thermocouples on the specimen

7.6.1

"A" class divisions, excluding

doors

The surface temperatures on the unexposed face of the test

specimen shall be measured by thermocouples located as shown in figures

7 and 8:

-

.1 five thermocouples, one at the centre of the

test specimen and one at the centre of each of the four quarters,

all positioned at least 100 mm away from the nearest part of any joints

and/or at least 100 mm away from the welds to any stiffeners;

-

.2 two thermocouples, one placed over each of

the central stiffeners and for a bulkhead at 0.75 height of the specimen

and for a deck at mid-length of the deck;

-

.3 two thermocouples, each placed over a vertical

(longitudinal) joint, if any, in the insulation system and positioned

for a bulkhead at 0.75 height of the specimen and for a deck at mid-length

of the deck;

-

.4 when a construction has two differently orientated

joint details, for example normal to each other, then two thermocouples

additional to those already described in paragraph 7.6.1.3 above shall

be used, one on each of two intersections;

-

.5 when a construction has two different types

of joint detail, then two thermocouples shall be used for each type

of joint;

-

.6 additional thermocouples, at the discretion

of the testing laboratory or Administration, may be fixed over special

features or specific construction details if it is considered that

temperatures higher than those measured by the thermocouples listed

above may result; and

-

.7 the thermocouples specified in subparagraphs

.4 to .6 above for measurements on bulkheads, e.g., over different

joint types or over joint intersections, shall, where possible, be

positioned in the upper half of the specimen.

7.6.2

"B" and "F" class divisions,

excluding doors

The surface temperatures on the unexposed face of the test

specimen shall be measured by thermocouples located as shown in figure

9:

-

.1 five thermocouples, one at the centre of the

test specimen and one at the centre of each of the four quarters,

all positioned at least 100 mm away from the nearest part of any joints;

-

.2 two thermocouples, each placed over a vertical

(longitudinal) joint, if any, in the division/insulation system and

positioned for a bulkhead at 0.75 height of the specimen and for a

deck/ceiling at mid-length of the deck/ceiling; and

-

.3 additional thermocouples, as required by paragraphs

7.6.1.4 to 7.6.1.7 above.

7.6.3

"A", "B" and "F" class doors

The surface temperatures on the unexposed face of the test

specimen shall be measured by:

-

.1 five thermocouples, one at the centre of the

door leaf and one at the centre of each of the four quarters of the

door leaf, all positioned at least 100 mm away from the edge of the

door leaf, from any stiffeners, from any door furniture and from any

special features or specific constructional details;

-

.2 if the door leaf incorporates stiffeners, two

additional thermocouples, one placed over each of two stiffeners in

the central portion of the door;

-

.3 additional thermocouples, at the discretion

of the testing laboratory or Administration, may be fixed over special

features or specific constructional details if it is considered that

temperatures higher than those measured by the thermocouples listed

above may result. Any additional thermocouples fixed to the door frame,

or to any part of the door leaf, which is closer than a distance of

100 mm from the gap between the edge of the door leaf and the frame

shall not be used for the purpose of classification of the test specimen,

and if provided are for information only;

-

.4 the thermocouples specified in paragraphs 7.6.3.2

and 7.6.3.3 above shall, where possible, be positioned in the upper

half of the specimen;

-

.5 additional thermocouples on the grille of a

"B" class door are not to be placed over the perforated area and in

a 100 mm wide zone around it;

-

.6 temperature measurements on a door which incorporates

a ventilation opening within its construction shall not be made over

the face of the ventilation grille(s);

-

.7 the door constructions, which incorporate a

top panel, shall always be tested with thermocouples on the unexposed

face of the top panel and on the joints and/or joining profiles at

a level 125 mm above the top of the door leaf. Height of the top panel

in the test specimen should be equal or greater than 225 mm; and

-

.8 when testing double-leaf door assemblies, the

requirements shall be applied to each door leaf separately.

7.7 Structural core temperature thermocouples

7.7.1 When testing a specimen with a structural

core other than steel, thermocouples shall be fixed to the core material

in positions corresponding to the surface thermocouples mentioned

in paragraph 7.6.1.1.

7.7.2 The thermocouples shall be fixed so that

their hot junctions are attached to the appropriate positions by suitable

means, including peening into the structural core. The wires shall

be prevented from becoming hotter than the junction. The first 50

mm shall be in an isothermal plane.

7.8 Measuring and recording equipment for thermocouples

The measuring and recording equipment shall be capable of

operating within the limits specified in standard ISO 834-1.

7.9 Cotton-wool pads

The cotton-wool pad employed in the measurement of integrity

shall consist of new, undyed and soft cotton fibres, 20 mm thick x

100 mm square, and shall weigh between 3 g and 4 g. It shall be conditioned

prior to use by drying in an oven at 100 ± 5°C for at least

30 min. After drying, it shall be allowed to cool to ambient temperature

within a desiccator, where it may be stored until needed to be used.

For use it shall be mounted in a wire frame, as shown in figure 10,

provided with a handle.

7.10 Gap gauges

Three types of gap gauge, as shown in figure 11, shall be

available for the measurement of integrity. They shall be made of

stainless steel of the diameter specified to an accuracy of ±

0.5 mm. They shall be provided with appropriate handles.

8 Method of Test

8.1 General

The test shall be carried out generally in accordance with

the standard ISO 834-1, except where amended by this section. The

procedures given in the following sections are supplementary to, an

elaboration of, or a deviation from the ISO requirements.

8.2 Commencement of test

8.2.1 Not more than 5 min before the commencement

of the test, the initial temperatures recorded by all thermocouples

shall be checked to ensure consistency and the datum values shall

be noted. Similar datum values shall be obtained for deformation,

and the initial condition of the test specimen shall be noted.

8.2.2 At the time of the test, the initial average

internal temperature and unexposed surface temperature of the specimen

shall be from 10°C to 35°C and shall be within 5°C of

the initial ambient temperature.

8.2.3 Prior to the commencement of the test the

furnace temperature shall be less than 50°C. The commencement

of the test shall be considered to be the moment when the programme

to follow the standard heating curve has been initiated.

The laboratory shall be virtually draught free during the

test. The ambient temperature shall be from 10°C to 35°C at

the commencement of the test and during the test the temperature shall

not decrease more than 5°C or increase more than 20°C for

all insulated separating elements while they are still satisfying

the insulation criterion.

8.3 Furnace control

8.3.1

Furnace temperature

8.3.1.1 The average temperature of the furnace

as derived from the furnace thermocouples specified in paragraph 7.3

shall be monitored and controlled such that it follows the relationship

(i.e. the standard heating curve):

where:

8.3.1.2 The following points are defined by the

above relationship:

-

.1 at the end of the first 5 min 576°C;

-

.2 at the end of the first 10 min 679°C;

-

.3 at the end of the first 15 min 738°C;

-

.4 at the end of the first 30 min 841°C; and

-

.5 at the end of the first 60 min 945°C.

8.3.1.3 The percentage deviation 'd' in the area

of the curve of the average temperature recorded by the specified

furnace thermocouples versus time from the area of the standard heating

curve shall be within:

| ± 15%

|

from t = 0 to 10

|

(1)

|

| ± (15-0.5(t-10))%

|

from t = 10 to 30

|

(2)

|

| ± (5-0.083(t-30))%

|

from t = 30 to 60

|

(3)

|

| ± 2.5%

|

from t = 60 and over

|

(4)

|

where:

|

d |

= |

(A – As ) x 1/As x 100, and

|

All areas shall be computed by the same method, i.e. by

the summation of areas at intervals not exceeding 1 min.

8.3.1.4 At any time after the first 10 min of

test, the temperature recorded by any thermocouple shall not differ

from the corresponding temperature of the standard time-temperature

curve by more than ± 100°C.

8.3.2.1 A linear pressure gradient exists over

the height of a furnace, and although the gradient will vary slightly

as a function of the furnace temperature, a mean value of 8 Pa per

metre height may be assumed in assessing the furnace pressure conditions.

The value of the furnace pressure shall be the nominal mean value,

disregarding rapid fluctuations of pressure associated with turbulence,

etc., and shall be established relative to the pressure outside the

furnace at the same height. It shall be monitored and controlled continuously

and by 5 min from the commencement of the test shall be achieved within

± 5 Pa and by 10 min from the commencement of the test shall

be achieved and maintained within ± 3 Pa.

8.3.2.2 For vertically orientated specimens the

furnace shall be operated such that a pressure of zero is established

at a height of 500 mm above the notional floor level to the test specimen.

However, for specimens with a height greater than 3 m, the pressure

at the top of the test specimen shall not be greater than 20 Pa, and

the height of the neutral pressure axis shall be adjusted accordingly.

8.3.2.3 For horizontally orientated specimens

the furnace shall be operated such that a pressure of 20 Pa is established

at a position 100 mm below the underside of the specimen.

8.4 Measurements and observations on the test specimen

8.4.1.1 All temperature measurements shall be

recorded at intervals not exceeding 1 min.

8.4.1.2 When calculating temperature rise on the

unexposed surface of the test specimen, this shall be done on an individual

thermocouple-by-thermocouple basis. The average temperature rise on

the unexposed surface shall be calculated as the average of the rises

recorded by the individual thermocouples used to determine the average

temperature.

8.4.1.3 For "A" class divisions, excluding doors,

the average temperature rise on the unexposed face of the specimen

shall be calculated from the thermocouples specified in paragraph

7.6.1.1 only.

8.4.1.4 For "B" and "F" class divisions, excluding

doors, the average temperature rise on the unexposed face of the specimen

shall be calculated from the thermocouples specified in paragraph

7.6.2.1 only.

8.4.1.5 For "A", "B" and "F" class doors, the

average temperature rise on the unexposed face of the specimen shall

be calculated from the thermocouples specified in paragraph 7.6.3.1

only. For a double-leaf door, all ten thermocouples used on both door

leaves shall be used for this calculation.

8.4.

Flaming on unexposed face

The occurrence and duration of any flaming on the unexposed

surface, together with the location of the flaming, shall be recorded.

In cases where it is difficult to identify whether or not there are

flames then the cotton-wool pad shall be applied to the area of such

disputed flaming to establish whether ignition of the pad can be initiated.

8.4.3.1 Tests with the cotton-wool pad are used

to indicate whether cracks and openings in the test specimen are such

that they could lead to the passage of hot gases sufficient to cause

ignition of combustible materials.

8.4.3.2 A cotton-wool pad is employed by placing

the frame within which it is mounted against the surface of the test

specimen, adjacent to the opening or flaming under examination, for

a period of 30 s, or until ignition (defined as glowing or flaming

) of the cotton-wool pad occurs (if this happens before the elapse

of the 30 s period). Small adjustments in position may be made so

as to achieve the maximum effect from the hot gases. A cotton-wool

pad shall be used only once.

8.4.3.3 The cotton-wool pad need not be used on

the unexposed face after the period relevant to the insulation classification

of the product.

8.4.3.4 Where there are irregularities in the

surface of the test specimen in the area of the opening, care shall

be taken to ensure that the legs of the support frame are placed so

that clearance between the pad and any part of the test specimen surface

is maintained during the measurements.

8.4.3.5 The cotton-wool pad shall be applied freely

and not necessarily parallel to the surface of the specimen, and not

always such that the crack or opening is central to the pad. The pad

shall be positioned in the flow of hot gases but shall never be positioned

such that any part of the pad is closer than approximately 25 mm from

any point of the test specimen. For example, to adequately evaluate

the hot gas leakage around a door it may be necessary to use the pad

both parallel and normal to the face of the door or possibly at an

oblique angle within the confines of the door frame.

8.4.3.6 The operator may make "screening tests"

to evaluate the integrity of the test specimen. Such screening may

involve selective short duration applications of the cotton-wool pad

to areas of potential failure and/or the movement of a single pad

over and around such areas. Charring of the pad may provide an indication

of imminent failure, but an unused pad shall be employed in the prescribed

manner for an integrity failure to be confirmed.

8.4.4.1 Tests with the gap gauges are used to

indicate whether cracks and openings in the test specimen are of such

dimensions that they could lead to the passage of hot gases sufficient

to cause ignition of combustible materials.

8.4.4.2 The gap gauges shall be used at intervals

which will be determined by the apparent rate of the specimen deterioration.

Two gap gauges shall be employed, in turn, and without undue force

to determine:

-

.1 whether the 6 mm gap gauge can be passed through

the specimen such that the gauge projects into the furnace, and can

be moved a distance of 150 mm along the gap; or

-

.2 whether the 25 mm gap gauge can be passed through

the specimen such that the gauge projects into the furnace.

Any small interruption to the passage of the gauge that

would have little or no effect upon the transmission of hot gases

through the opening shall not be taken into account, e.g., small fastening

across a construction joint that has opened up due to distortion.

8.4.4.3 If gaps in "A" or "B" class divisions

are fully or partly sealed by intumescent materials, the gap gauge

test shall be performed as if no intumescent material is present.

8.4.4.4 For doors mounted in a three-sided frame,

the change of gap at the bottom of the door as measured by a horizontally-held

gap gauge shall not increase by more than 12 mm along the bottom edge

of the door. 12 mm gap gauge can be used for the purpose of examining

the increase of such gap. The edges of the door above the horizontal

plane along the bottom of the door should be checked in the same manner

as the four-sided framed door.

The deflection of an "A", "B" or "F" class test specimen,

and additionally in the case of a door the maximum displacement of

each corner of the door leaf relative to the door frame, shall be

recorded during the test. These deflections and displacements shall

be measured with an accuracy of ± 2 mm.

Observations shall be made of the general behaviour of the

specimen during the course of the test and notes concerning the phenomena

such as cracking, melting or softening of the materials, spalling

or charring, etc., of materials of construction of the test specimen

shall be made. If quantities of smoke are emitted from the unexposed

face this shall be noted in the report. However, the test is not designed

to indicate the possible extent of hazard due to these factors.

8.5 Duration of testing

8.5.1

"A" class divisions

For all "A" class divisions, including those with doors,

the test shall continue for a minimum of 60 min. However, when the

specimen is of an "A" class division, with a structural steel core

which is imperforate (e.g., without a door), and where insulation

is provided to the exposed face only (i.e. the structural steel core

is the unexposed face of the construction), it is permitted to terminate

the test prior to 60 min once the unexposed-face temperature-rise

limits have been exceeded.

8.5.2

"B" and "F" class divisions

For all "B" and "F" class divisions, including those with

doors, the test shall continue for a minimum of 30 min.

8.5.3

Termination of the test

The test may be terminated for one or more of the following

reasons:

-

.1 safety of personnel or impending damage to

equipment;

-

.2 attainment of selected criteria; or

-

.3 request of the sponsor.

The test may be continued after failure under subparagraph

.2 above to obtain additional data.

9 Test Report

The test report shall include the following information

as a minimum. A clear distinction shall be made between the data provided

by the sponsor and the data determined by the test:

-

.1 reference that the test was carried out in

accordance with part 3 of the 2010 FTP Code (see also subparagraph

.2 below);

-

.2 any deviations from the test method;

-

.3 name and address of the testing laboratory;

-

.4 date and identification number of the report;

-

.5 name and address of the sponsor;

-

.6 name and/or identification of the product tested;

-

.7 the name of the manufacturer of the test specimen

and of the products and components used in the construction;

-

.8 type of the product, e.g., bulkhead, ceiling,