Section

5 Welded joints and connections

5.1 General

5.1.1 Requirements

are given in this Chapter for welding connection details, aluminium/steel

transition joints, steel/wood connection, rivetting of light structure

and adhesive bonding.

5.1.2 Welded

joints are to be detailed such that crevices or inaccessible pockets

capable of retaining dirt or moisture are avoided. Where cavities

are unavoidable, they are to be sealed by welding or protective compounds

or made accessible for inspection and maintenance.

5.2 Weld symbols

5.2.1 Weld

symbols, where used, are to conform to a recognised National or International

Standard. Details of such Standards are to be indicated on the welding

schedule, which is to be submitted for appraisal.

5.3 Welding schedule

5.3.1 A welding

schedule containing not less than the following information is to

be submitted:

-

Weld throat thickness

or leg lengths.

-

Grades, tempers

and thicknesses of materials to be welded.

-

Locations, types

of joints and angles of abutting members.

-

Reference to welding

procedures to be used.

-

Welded connections

to steel castings.

5.4 Butt welds

5.4.1 All

structural butt joints are to be made by means of full penetration

welds and, in general, the edges of plates to be joined by welding

are to be bevelled on one or both sides of the plates. Full details

of the proposed joint preparation are to be included in the approval

welding procedure.

5.4.2 Where

butt welds form a T-junction, the leg of the T is, where practicable,

to be completed first including any back run. During the welding operation

special attention is to be given to the completion of the weld at

the junction, which is to be chipped back to remove crater cracks,

etc. before the table is welded.

5.5 Fillet welds

5.5.1 The

throat thickness of fillet welds is to be determined from:

|

Throat thickness |

= |

t

p x weld factor x mm mm

|

where

|

s

|

= |

the

length of correctly proportioned weld fillet, clear of end craters,

in mm, and is to be 10 x plate thickness, t

p,

or 75 mm, whichever is the lesser, but in no case to be taken less

than 40 mm

|

|

d

|

= |

the

distance between successive weld fillet, in mm |

Weld factors are contained in Table 6.5.1 Weld factors and Figure 6.5.1 Weld fillet dimensions

NOTE: for

double continuous fillet welding is to be taken is to be taken

as 1, see

Vol 1, Pt 6, Ch 6, 5.8 Double continuous fillet welding 5.8.1.

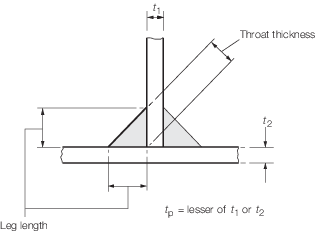

Figure 6.5.1 Weld fillet dimensions

5.5.2 For

ease of welding, it is recommended that the ratio of the web height

to the flange breadth is greater than or equal to 1,5, see

Figure 6.5.2 Web height/flange breadth ratio

Figure 6.5.2 Web height/flange breadth ratio

5.5.3 The

leg length of the weld is to be not less than  times the specified throat thickness. times the specified throat thickness.

5.5.4 The

plate thickness t

p to be used in Vol 1, Pt 6, Ch 6, 5.5 Fillet welds 5.5.1 is generally to be that of

the thinner of the two parts being joined. Where the difference in

thickness is considerable, the size of fillet weld will be specially

considered.

5.5.5 Where

the thickness of the abutting member of the connection (e.g. the web

of a stiffener) is greater than 15 mm and exceeds the thickness of

the table member (e.g. plating), the welding is to be double continuous

and the throat thickness of the weld is to be not less than the greatest

of the following:

-

0,21 x thickness

of the table member. The table member thickness used need not exceed

30 mm.

-

0,21 (0,27 in

tanks) x half the thickness of the abutting member.

-

As required by

item 3 in Table 6.5.2 Throat thickness limits

Table 6.5.1 Weld factors

| Item

|

Weld factor

|

Remarks

|

| (1)

|

General

application:

|

|

except as

required below

|

| Shell

envelope boundary, including sea chests and hull penetrations

|

Full

penetration

|

For hull

penetrations, fitted with a flange or other support, equivalent arrangements

may be considered.

|

| Watertight

plate boundaries

|

0,34

|

|

| Non-tight

plate boundaries

|

0,13

|

|

| Longitudinals, frames, beams, and other secondary members to

shell, deck or bulkhead plating

|

0,10

|

|

| 0,13

|

in tanks

|

| 0,21

|

in way

of end connections

|

| Panel

stiffeners, etc.

|

0,10

|

|

| Overlap welds

generally

|

0,27

|

|

| Longitudinals of the flat-bar type to plating

|

|

See

Vol 1, Pt 6, Ch 6, 5.5 Fillet welds 5.5.5

|

| (2)

|

Bottom

construction in way of tanks:

|

|

|

| Non-tight

centre girder:

|

|

|

|

to keel

|

0,27

|

|

|

to inner bottom

|

0,21

|

no

scallops

|

| Non-tight boundaries of floors, girders and brackets

|

0,21

|

in way of

0,2 x span at ends

|

| 0,27

|

in way of

brackets at lower end of main frame

|

| Watertight bottom girders

|

0,34

|

|

| Connection of girder to inner bottom

in way of longitudinal bulkheads supported on inner bottom

|

0,44

|

|

| Inner bottom longitudinals or reverse

frames

|

0,13

|

|

| Connection of floors to inner bottom

in way of bulkheads, supported on inner bottom. The supporting floors are to

be continuously welded to the inner bottom

|

0,44

|

Weld size based on floor thickness

Weld material compatible with floor material

|

| (3)

|

Hull

framing:

|

|

|

| Webs of web

frames and stringers:

|

|

|

| to

shell

|

0,16

|

|

| to face

plate

|

0,13

|

|

| Tank side brackets to shell and inner

bottom

|

0,34

|

|

| (4)

|

Decks and

supporting structure:

|

|

|

|

|

Strength

deck plating to shell

|

|

as shown in Table 6.5.5 Weld connection of strength deck

plating to sheerstrake but alternative proposals will be

considered

|

|

|

Other decks

to shell and bulkheads (except where forming tank boundaries)

|

0,21

|

generally

continuous

|

|

|

Webs of

cantilevers to deck and to shell in way of root bracket

|

0,44

|

|

|

|

Webs of

cantilevers to face plate

|

0,21

|

|

|

|

Pillars:

fabricated

|

0,10

|

|

|

|

end connections

|

0,34

|

see Note

|

|

|

end connections (tubular)

|

full

penetration

|

|

|

|

Girder web

connections and brackets in way of pillar heads and heels and end

brackets

|

0,21

|

continuous

|

|

|

Girder web

connections general

|

0,1

|

|

| (5)

|

Bulkheads

and tank construction:

|

|

|

|

|

Plane,

double plate and corrugated watertight bulkhead boundary at bottom, bilge,

inner bottom, deck and connection to shelf plate, where fitted

|

0,44

|

Weld size

to be based on thickness of bulkhead platingWeld material to be compatible

with bulkhead plating material

|

|

|

Shelf plate

connection to stool

|

0,44

|

Weld size to

be based on thickness of stool at junction with shelf plate. Weld material

to be compatible with stool material

|

|

|

Plane,

double plate and corrugated main watertight bulkhead boundaries

|

0,44

|

|

|

|

– Boundary at bottom, bilge, inner bottom and deck

|

|

|

|

|

– Connection of bulkhead plating to side shell

|

0,44

|

|

|

|

Deep tank

horizontal boundaries at vertical corrugations

|

Full

penetration

|

|

|

|

Secondary

members where acting as pillars

|

0,13

|

|

|

|

Non-watertight pillar bulkhead boundaries

|

0,13

|

|

|

|

Perforated flats and wash bulkhead

boundaries

|

0,10

|

|

| (6)

|

Structure

in machinery space:

|

|

|

|

|

Centre

girder to keel and inner bottom

|

0,27

|

no scallops

to inner bottom

|

|

|

Floors to

centre girder in way of engine, thrust and boiler bearers

|

0,27

|

|

|

|

Floors and

girders to shell and inner bottom

|

0,21

|

|

|

|

Main engine

foundation girders:

|

|

|

|

|

to top plate

|

deep penetration to depend on design

|

edge to be

prepared with maximum root 0,33tp deep penetration generally

|

|

|

to hull structure

|

|

|

Floors to

main engine foundation girders

|

0,27

|

|

|

|

Brackets,

etc. to main engine foundation girders

|

0,21

|

|

|

|

Transverse and longitudinal framing

to shell

|

0,13

|

|

| (7)

|

Construction

forward 0,75L

R:

|

|

|

|

|

Floors and

girders to shell and inner bottom

|

0,21

|

|

|

|

Bottom

longitudinals to shell

|

0,13

|

|

|

|

Transverse

and longitudinal side framing to shell

|

0,13

|

|

|

|

Tank side

brackets to frame and inner bottom

|

0,34

|

|

|

|

Panting

stringers to shell and frames

|

0,34

|

|

|

|

Fore peak

construction:

|

|

|

|

|

all internal structure

|

0,13

|

unless a greater weld factor is

required

|

| (8)

|

After peak

construction:

|

|

|

|

|

All internal structure and stiffeners on afterpeak

bulkhead

|

0,21

|

unless a

greater weld factor is required

|

| (9)

|

Superstructure and deckhouses:

|

|

|

|

|

Connection

of external bulkheads to deck

|

0,34

|

1st and 2nd

tier erections

|

|

|

|

0,21

|

elsewhere

|

|

|

Internal

bulkheads

|

0,13

|

|

| (10)

|

Steering

control systems:

|

|

|

|

|

Rudder:

|

|

|

|

|

Fabricated mainpiece and mainpiece to side plates and

webs

|

0,44

|

|

|

|

Slot welds inside plates

|

0,44

|

|

|

|

Remaining construction

|

0,21

|

|

|

|

Fixed and steering nozzles:

|

|

|

|

|

Main structure

|

0,44

|

|

|

|

Elsewhere

|

0,21

|

|

|

|

Fabricated

housing and structure of thruster units, stabilisers, etc.:

|

|

|

|

|

Main structure

|

0,44

|

|

|

|

Elsewhere

|

0,21

|

|

| (11)

|

Miscellaneous fittings and equipment:

|

|

|

|

|

Rings for

manhole type covers, to deck or bulkhead

|

0,34

|

|

|

|

Frames of

shell and weathertight bulkhead doors

|

0,34

|

|

|

|

Stiffening

of doors

|

0,21

|

|

|

|

Ventilator,

air pipe, etc. coamings to deck

|

0,34

|

|

|

|

Ventilator,

etc. fittings

|

0,21

|

|

|

|

Scuppers

and discharges, to deck

|

0,44

|

|

|

|

Masts,

derrick posts, crane pedestals, etc. to deck

|

0,44

|

full

penetration welding may be required

|

|

|

Deck

machinery seats to deck

|

0,21

|

generally

|

|

|

Mooring

equipment seats

|

0,21

|

generally,

but increased or full penetration welding may be required

|

|

|

Bulwark

stays to deck

|

0,21

|

|

|

|

Bulwark

attachment to deck

|

0,34

|

|

|

|

Guard rails,

stanchions, etc. to deck

|

0,34

|

|

|

|

Bilge keel

ground bars to shell

|

0,34

|

Continuous

fillet weld, minimum throat thickness 4 mm

|

|

|

Bilge keels

to ground bars

|

0,21

|

Continuous

fillet weld,minimum throat thickness 3 mm

|

|

|

Fabricated

anchors

|

full

penetration

|

|

|

|

Raft

seatings

|

0,27

|

|

|

|

Weapon

seatings

|

0,44

|

full

penetration welding may be required

|

Note Where pillars are fitted inside tanks or under watertight

flats, the end connection is to be such that the tensile stress in the

weld does not exceed 108 N/mm2.

|

Table 6.5.2 Throat thickness limits

| Item

|

Throat thickness, in mm

|

| Minimum

|

Maximum

|

| (1)

|

Double continuous welding

|

0,21t

p

|

0,44t

p

|

| (2)

|

Intermittent welding

|

0,27t

p

|

0,44t

por 4,5

|

| (3)

|

All welds, overriding minimum:(a) Plate thickness t

p ≤ 7,5 mmHand or automatic weldingAutomatic deep

penetrationwelding

|

3,0

|

-

|

| 3,0

|

-

|

| (b) Plate thickness t

p > 7,5 mmHand or automatic weldingAutomatic deep

penetrationwelding

|

3,25

|

-

|

| 3,0

|

-

|

Note

1. In all cases, the limiting value is to

be taken as the greatest of the applicable values given above.

Note

2. Where t

p exceeds 25 mm, the limiting values may be calculated

using a notional thickness equal to 0,5 (t

p + 25) mm.

Note

3. The maximum throat thicknesses shown

are intended only as a design limit for the approval of fillet welded

joints. Any welding in excess of these limits is to be to the

Surveyor's satisfaction.

|

5.6 Throat thickness limits

5.7 Single sided welding

5.7.1 Where

the main welding is carried out from one side only, this should be

in accordance with the approved single sided welding procedure.

5.7.2 Where

internal access for welding is impracticable, backing bars are to

be fitted in way of butt welds, or alternative means of obtaining

full penetration welds are to be agreed. Backing bars may be permanent

or temporary, subject to agreement.

5.7.3 Permanent

backing bars are to be of the same material as the base metal and

of thickness not less than the thickness of the plating being joined

or 4 mm, whichever is the lesser. The weld is to be thoroughly fused

to the backing bar, subject to agreement.

5.7.4 Backing

bars are to be continuous for the full length of the weld and joints

in the backing bar are to be by full penetration welds, ground smooth.

5.7.5 Temporary

backing bars for single sided welding may be glass tape, ceramic,

or steel of the same grade as the base metal.

5.7.6 Temporary

non-metallic backing bars are to be suitably grooved in way of the

weld to ensure full penetration.

5.8 Double continuous fillet welding

5.8.2 Double

continuous fillet welding is to be adopted in the following locations

and may be used elsewhere if desired:

-

Boundaries of

weathertight decks and erections and all other openings.

-

Boundaries of

tank and watertight compartments.

-

Main engine and

equipment seatings and rafts.

-

Bottom framing

structure in machinery spaces of high speed ships.

-

The side and bottom

shell structure in the impact area of high speed ships.

-

Structure in way

of rudders, propeller brackets, stabilisers, thrusters, bilge keels,

foundations and other areas subject to high stresses.

-

The shell structure

in the vicinity of the propeller blades.

-

Stiffening members

to plating in way of end connections scallops and of end brackets

to plating in the case of lap connections.

-

Face flats to

webs of built-up/fabricated stiffening members in way of knees/end

brackets and for a distance beyond such knees/end brackets of not

less than the web depth of stiffener in way.

-

All structure

in the after peak and after peak bulkhead stiffeners.

-

Forward tanks.

-

Lap welds in tanks.

-

Primary and secondary

members to bottom shell forward of 0,7L.

-

Where Vol 1, Pt 6, Ch 6, 5.5 Fillet welds 5.5.5 applies.

-

Other connections

or attachments where necessary in particular minor items to high tensile

steel plating.

5.9 Intermittent and single sided fillet welding

5.9.2 As an

alternative to intermittent welding, single sided welding may be used.

Only mechanised single sided welding is acceptable.

5.9.3 Where

staggered intermittent or single sided fillet welding is used, the

welding is to be made continuous round the ends of brackets, lugs,

scallops, etc.

5.9.4 Staggered

intermittent or single sided fillet welding is not to be used in the

bottom shell structure of high speed ships.

5.9.5 Chain

intermittent welding may be used, outside of the impact area in the

bottom shell structure of high speed ships.

5.9.6 Scalloped

construction, intermittent or single sided fillet welding is not to

be used in structure on or below the strength deck of ships with shock

enhancement or in structure strengthened for blast enhancement, see

Vol 1, Pt 4, Ch 2 Military Load Specification.

5.9.7 Scalloped

construction, intermittent or single sided fillet welding is not to

be used in structure complying with the requirements of the internal

blast station.

5.9.8 For

ships with a shock enhanced notation, the extent of intermittent or

single sided fillet welding will be specially considered on the basis

of the threat levels

5.10 Connections of primary structure

5.10.1 Weld

factors for the connections of primary structure are given in Table 6.5.3 Connections of primary

structure.

Table 6.5.3 Connections of primary

structure

| Primary member face area, in cm2

|

Position(1)

|

Weld factor

|

| In tanks

|

In

dry spaces

|

| Exceeding

|

Not exceeding

|

To face

plate

|

To plating

|

To face plate

|

To plating

|

|

|

30,0

|

At ends

|

0,21

|

0,27

|

0,21

|

0,21

|

| Remainder

|

0,10

|

0,16

|

0,10

|

0,13

|

| 30,0

|

65,0

|

At ends

|

0,21

|

0,34

|

0,21

|

0,21

|

|

|

|

Remainder

|

0,13

|

0,27

|

0,13

|

0,16

|

| 65,0

|

95,0

|

At ends

|

0,34

|

0,44(3)

|

0,21

|

0,27

|

|

|

|

Remainder

|

0,27(2)

|

0,34

|

0,16

|

0,21

|

| 95,0

|

130,0

|

At ends

|

0,34

|

0,44(3)

|

0,27

|

0,34

|

|

|

|

Remainder

|

0,27(2)

|

0,34

|

0,21

|

0,27

|

| 130,0

|

|

At ends

|

0,44

|

0,44(3)

|

0,34

|

0,44(2)

|

|

|

|

Remainder

|

0,34

|

0,34

|

0,27

|

0,34

|

Note

1. The weld factors ‘at ends’ are to be

applied for 0,2 x the overall length of the member from each end, but

at least beyond the toes of the member end brackets. On vertical webs

the increased welding may be omitted at the top, but is to extend at

least 0,3 x overall length from the bottom.

Note

2. Where the web plate thickness is

increased locally, the weld size may be based on the thickness clear

of the increase, but is to be not less than 0,34 x the increased

thickness.

Note

3. The weld factor of the connection of

bottom transverses to shell, and of side transverses to shell and

vertical webs to longitudinal and transverse bulkheads all in the

lower half depth, is to be not less than 0,34.

Note

4. The final throat thickness of the weld

fillet to be not less than 0,34t

p in oil tanks.

|

5.10.2 The

weld connection to shell, deck or bulkhead is to take account of the

material lost in the notch where longitudinals or stiffeners pass

through the member. Where the width of notch exceeds 15 per cent of

the stiffener spacing, the weld factor is to be multiplied by:

5.10.3 Where

direct calculation procedures have been adopted, the weld factors

for the 0,2 x overall length at the ends of the members will be considered

in relation to the calculated loads.

5.11 Primary and secondary member end connection welds

5.11.1 Welding

of end connections of primary members is to be such that the area

of welding is not less than the cross-sectional area of the member,

and the weld factor is to be not less than 0,34 in tanks or 0,27 elsewhere.

5.11.3 The

area of weld, A

w, is to be applied to each

arm of the bracket or lapped connection.

5.11.4 Where

a longitudinal strength member is cut at a primary support and the

continuity of strength is provided by brackets, the area of weld is

to be not less than the crosssectional area of the member.

5.11.6 The

throat thickness limits given in Table 6.5.2 Throat thickness limits are to be complied with.

Table 6.5.4 Primary and secondary member end

connection welds

| Connection

|

Weld area, A

w, in cm2

|

Weld factor

|

| (1)

|

Stiffener welded direct to plating

|

0,25A

s or 6,5 cm2whichever is the greater

|

0,34

|

| (2)

|

Bracketless connection of stiffeners or stiffener lapped to

bracket or bracket lapped to stiffener:(a) in dry space(b) in tank(c) in

0,15L forward

|

1,2  1,4 1,4  as (a) or (b) as (a) or (b)

|

0,270,340,34

|

| (3)

|

Bracket welded to face of stiffener and bracket connection

to plating

|

—

|

0,34

|

| (4)

|

Stiffener to plating for 0,1 x span at ends, or in way of

end bracket if that be greater

|

—

|

0,34

|

| Symbols

|

|

A

s

|

= |

cross-sectional area of the stiffener, in

cm2

|

|

A

w

|

= |

the area of the weld, in cm2, and is

calculated as total length of weld, in cm, x throat thickness, in

cm |

|

Z

|

= |

the section modulus, in cm2, of the

stiffener on which the scantlings of the bracket are based. |

|

|

|

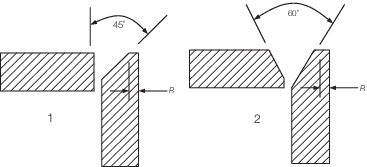

Table 6.5.5 Weld connection of strength deck

plating to sheerstrake

| Item

|

Stringerplate

thickness,mm

|

Weld type

|

| 1

|

t ≤ 15

|

Single vee preparation to provide included angle

of 45º with root R ≤ 1/3 t in conjunction with a continuous

fillet weld having a weld factor of 0,39

|

| 2

|

15 < t ≤ 25

|

Double vee preparation to provide included angle

of 60° with root R ≤ 1/3 t in conjunction with a continuous

fillet weld having a weld factor of 0,39

|

| 3

|

t > 25

|

Triple vee preparation to provide included

angles of 50° with root R ≤ 1/3 t but not to exceed 10 mm

|

|

Note

1 Welding procedure, including joint

preparation, is to be specified. Procedure is to be qualified and

approved for individual Builders.

Note

3 For thickness t in excess of 20

mm the stringer plate may be bevelled to achieve a reduced thickness

at the weld connection. The length of the bevel is in general to be

based on a taper not exceeding 1 in 3 and the reduced thickness is in

general to be not less than 0,65 times the thickness of stringer plate

or 20 mm, whichever is the greater.

Note

4 Alternative connections will be

considered.

|

5.12 Tank boundary penetrations

5.12.1 Where

structural members pass through the boundary of a tank, and leakage

into the adjacent space could be hazardous or undesirable, full penetration

welding is to be adopted for the members for at least 150 mm on each

side of the boundary. Alternatively a small scallop of suitable shape

may be cut in the member close to the boundary outside the compartment,

and carefully welded all round.

5.13 Intersection of primary and secondary members

5.13.1 The

weld area of the connections is to be generally not less than the

following:

-

Connection of

primary member stiffener to the secondary member:

|

A

w

|

= |

0,25A

f or 6,5 cm2, whichever

is the greater, corresponding to a weld factor of 0,34 for the throat

thickness

|

-

Connection of

secondary member to the web of the primary member:

|

A

w

|

= |

0,5 corresponding to a weld factor of 0,34 in tanks or 0,27

in dry spaces for the throat thickness. corresponding to a weld factor of 0,34 in tanks or 0,27

in dry spaces for the throat thickness.

|

where

|

A

w

|

= |

weld area, in cm2, and is calculated as total length

of weld, in cm, multiplied by throat thickness, in cm

|

|

A

f

|

= |

cross-sectional area of the primary member web stiffener, in

cm2, in way of connection

|

|

Z

|

= |

the

section modulus, in cm3, of the secondary member.

|

|