Section

8 Double bottom structures

8.1 General

8.1.1 The

requirements of this Section, unless specified otherwise, are applicable

to all ship types, NS1, NS2 and NS3.

8.1.2 The basic structural scantlings of NS1 ships are to be determined in

accordance with Vol 1, Pt 6, Ch 3, 3 NS1 scantling determination The basic structural scantlings of NS2 and NS3

ships are to be determined in accordance with Vol 1, Pt 6, Ch 3, 4 NS2 and NS3 scantling determination. The scantlings of the double bottom structure are also to

comply with the appropriate minimum requirements given in Vol 1, Pt 6, Ch 3, 2 Minimum structural requirements The arrangements of double bottoms are to comply with the

requirements of Vol 1, Pt 3, Ch 3, 2.6 Rudder force

8.1.4 This

Section provides for longitudinal or transverse framing in the double

bottom, but for NS1 and NS2 ships longitudinal framing is in general

to be adopted. See

Vol 1, Pt 3, Ch 2, 3.1 General

8.2 Centreline girder

8.2.3 The

depth of the double bottom and centreline girder is to be not less

than 630 mm and it is to be sufficient to give access to all of the

double bottom.

8.2.4 Where

appropriate, vertical stiffeners are to be fitted at every bracket

floor. They are to have a depth not less than the depth of the tank

top frame or 150 mm, whichever is the greater. For NS2 and NS3 ships

stiffeners are to have a depth of not less than 1,65L

R mm

with a minimum of 50 mm. The thickness is to be as required for the

girder.

8.3 Side girders

8.3.1 The

thickness of the side girders is not to be less than that of the plate

floors. The buckling requirements of Vol 1, Pt 6, Ch 2, 3 Buckling are to be satisfied.

8.4 Plate floors

8.4.1 The

thickness need not be greater than 15 mm but without suitable stiffening

the ratio of depth of floor at the centre to thickness must be less

than 130.

8.4.2 Vertical

stiffeners are to be fitted to all plate floors at each longitudinal.

Each stiffener is to have a depth of not less than 10t

w or 50 mm and a thickness of not less than t

w,

where t

w is the thickness of the plate floor

as calculated in Vol 1, Pt 6, Ch 3, 2 Minimum structural requirements. For

NS1 ships, the depth of stiffeners is not to be less than 150 mm.

8.5 Bracket floors

8.5.1 Between

plate floors, the shell and inner bottom plating centreline girders

and side girders may be supported by bracket floors. The brackets

are to have the same thickness as plate floors and are to be stiffened

on the unsupported edge.

8.5.2 Where

struts are fitted to reduce the unsupported span of the frames, reverse

frames and longitudinals, they are to have a cross-sectional area

of not less than:

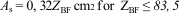

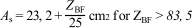

-

or or

-

where Z

BF is the modulus, in cm3,

of the frame or longitudinal based on the effective length between

floors as defined in Vol 1, Pt 6, Ch 2, 2.6 Determination of span length

8.6 Additional requirements for watertight floors

8.7 Inner bottom plating

8.8 Inner bottom longitudinals

8.8.2 Higher

tensile steel inner bottom longitudinals are to be continuous as far

as practicable throughout the length of the ship.

8.9 Double bottom tanks

8.10 Margin plates

8.10.1 A

margin plate, if fitted, is to have a thickness as required for inner

bottom plating.

8.11 Double bottom structure in machinery rooms

8.11.2 The

scantlings of floors clear of the main engine seatings, are generally

to be as required in Vol 1, Pt 6, Ch 3, 8.4 Plate floors. In

way of engine seatings the floors are to be increased in thickness, see

Vol 1, Pt 6, Ch 3, 7.5 Single bottom structure in machinery spaces and Vol 1, Pt 6, Ch 3, 13 Machinery and raft seatings

8.11.3 Where

the double bottom is longitudinally framed and transverse floors are

fitted in way of the engine seatings as required by Vol 1, Pt 3, Ch 2, 6.6 Double and single bottom structure 6.6.4, no additional

longitudinal stiffening is required in way of the engines other than

the main engine girders, provided that the spacing of girders does

not exceed 1,5 times the normal spacing of longitudinals. Where this

spacing of girders is exceeded, shell longitudinals are to be fitted.

These are to scarf into the longitudinal framing clear of the machinery

spaces. The scantlings of the longitudinals are to be determined in

accordance with the appropriate requirements for bottom shell longituduals

using a minimum span of 1,3 m.

|